2D laser cuttingAlmost any contour you desire, DIN parts, such as discs, washers, spacers, according to your dataset, drawing, sketch or sample up to a max. machining size of 4000 mm x 2000 mm for steel with a thickness up to 35 mm, stainless steel (INOX) up to 30 mm, as well as for oxide-free copper (Cu), bronze (CuSn), brass (CuZn), plastics, Plexiglas®, wood, aluminium, steel or stainless steel mesh, special steels, Damascus and tool steel.

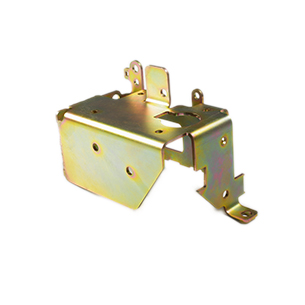

3D laser cutting

Almost any contour you desire according to your dataset, drawing, sketch or sample with a temperature of approx. 12,000° C. Maximum cutting size: 1250 mm x 1250 mm x 600 mm for steel, copper (Cu), bronze (CuSn), brass (CuZn), aluminium, special steels, stainless steel (INOX), plastics and Plexiglas®.

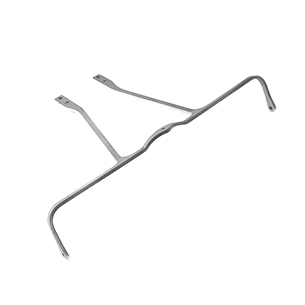

Pipe laser cutting

Almost any contour you desire according to your dataset, drawing, sketch or sample with a temperature of approx. 12,000° C. Maximum cutting size: Round pipes: 3000 mm x Ø600 mm / alternatively 12,000 mm x Ø150 mm Rectangular pipes: 6000 mm x Ø200 mm made from: steel, copper (Cu), bronze (CuSn), brass (CuZn), aluminium, special steels and stainless steel (INOX).

Profile laser cutting

Almost any contour you desire according to your dataset, drawing, sketch or sample with a temperature of approx. 12,000° C. Maximum cutting size: 6000 mm x Ø300 mm. U-profile, L-profile, double T-profile or I-profile. Steel, copper (Cu), bronze (CuSn), brass (CuZn), aluminium, special steels and stainless steel (INOX).

Laser cutting involves separating materials using a laser beam. Almost every type of material – such as metals but also organic materials – can be cut using this method. This process is used where complex outlines and precise, quick machining and/or non-contact and force-free machining are desired. Laser cutting is an economical solution even for small quantities.