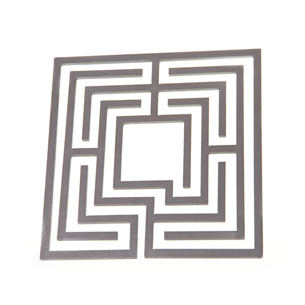

2D waterjet cuttingAlmost any contour you desire, DIN parts, such as discs, washers and spacers, according to your dataset, drawing, sketch or sample up to a size of 3000 mm x 2000 mm. Hardened materials can also be cut without any problems with a water pressure of up to 6,000 bar: steel, special steels, tool steel, titanium, casting iron, stainless steel (INOX), aluminium, plastics, wood, Arboform, glass, marble, tiles, Plexiglas®, bulletproof glass, etc.

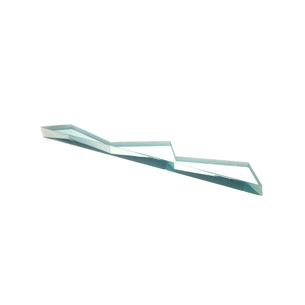

3D waterjet cutting

Almost any contour you desire. Up to a size of 3000 mm x 2000 mm x 400 mm for steel, special steels, tool steel, titanium, casting iron, stainless steel (INOX), aluminium, plastics, wood, Arboform, glass, marble, tiles, Plexiglas®, bulletproof glass, etc.

In waterjet cutting, a focussed jet of water is "shot" out of a nozzle under high pressure (up to 6,000 bar) onto the material to be cut. An abrasive medium (garnet sand) is added to the water to improve the cutting performance. The cutting contour is defined by using modern CNC control systems. This process is an attractive solution when other cutting processes have reached their limits, e.g. in the machining of very thick, highly reflective or very thermally conductive materials.